Cutting-edge Laser Technology Enhances Memorial Engraving

Quicker, higher-quality, and more durable engravings are now possible thanks to Earth Anchors’ latest investment: a galvomatic fibre laser engraver.

Advanced Engraving Technology

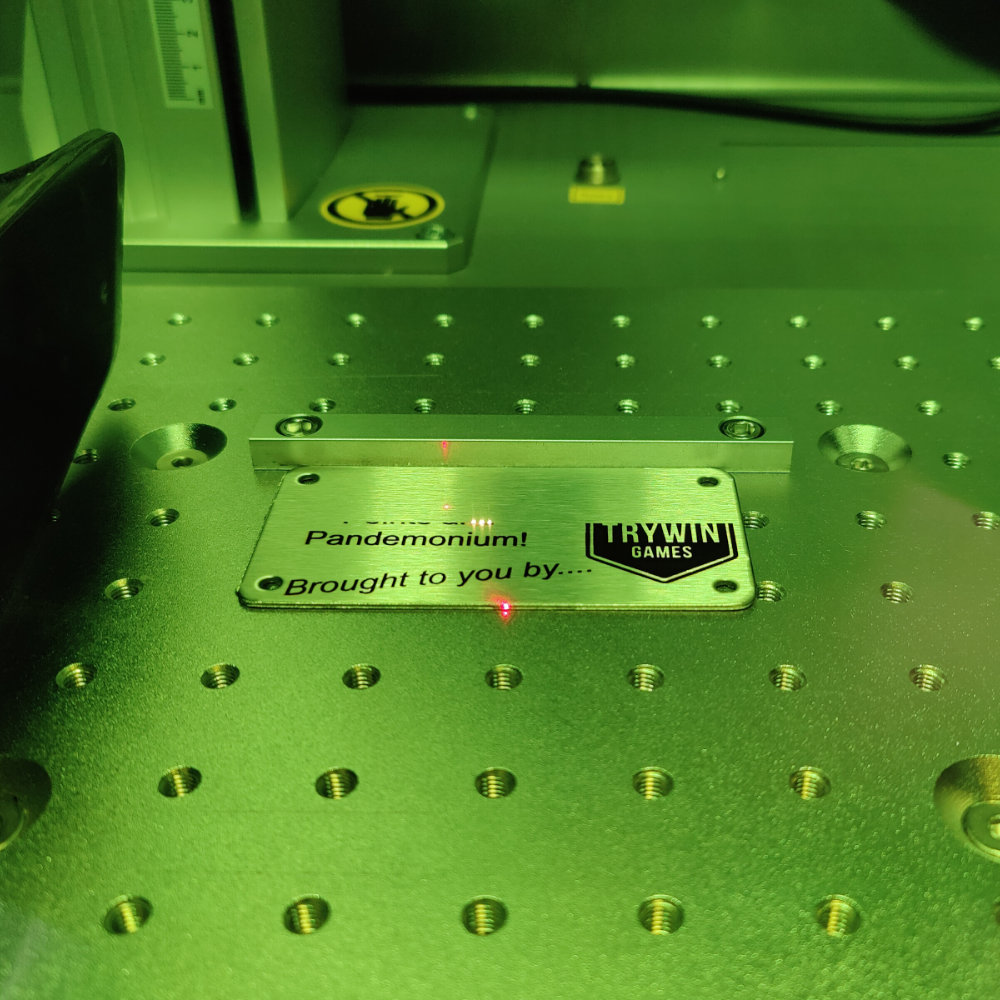

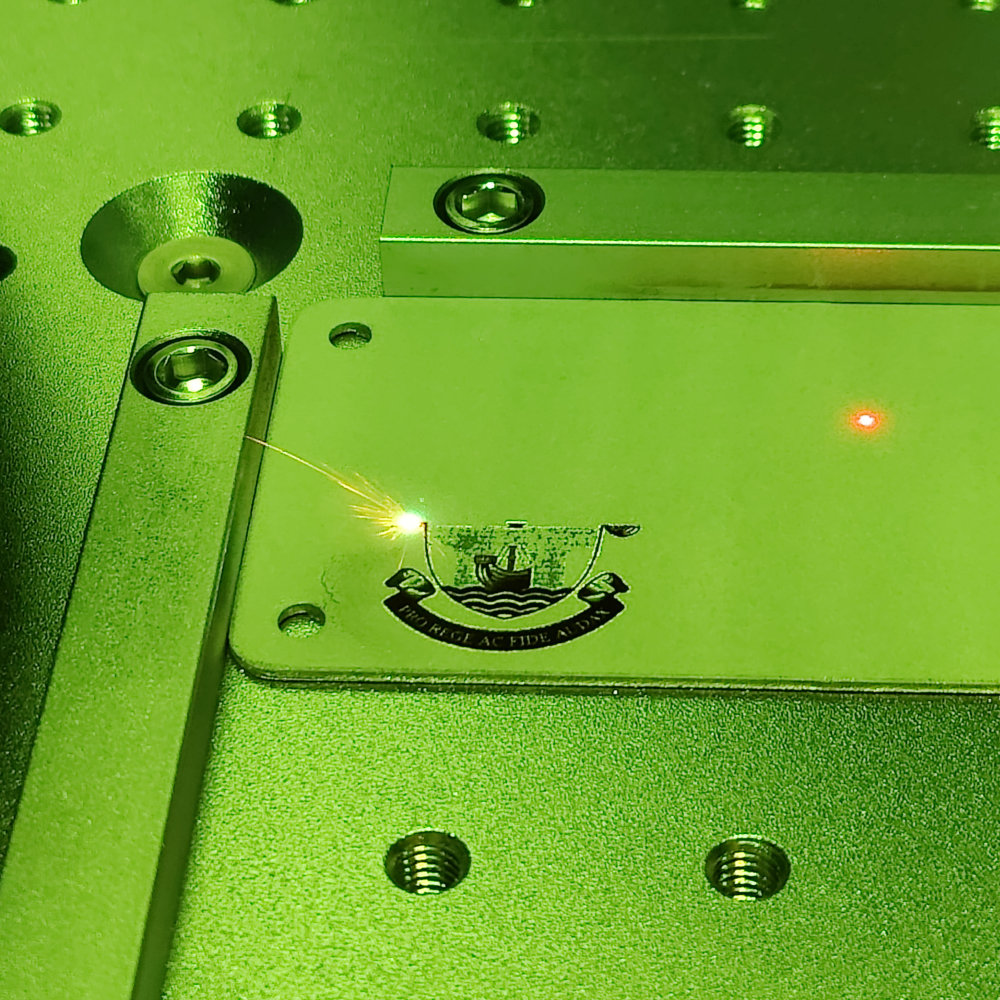

Earth Anchors has recently invested in a state-of-the-art laser engraver that uses a galvomatic head to direct its laser beam via tilting mirrors. This technology enables faster and more precise engraving compared with conventional methods.

Why the Upgrade?

The company continually looks for new methods to improve production efficiency. By adopting advanced equipment, Earth Anchors gains greater flexibility to explore new engraving techniques and provide enhanced services to its customers.

How It Works

The galvomatic head operates with two mirrors that can direct a laser beam at speeds of up to 10,000mm per second. The laser heats the steel until it changes colour through a process called tempering. Unlike traditional CO₂ laser engravers, which often require strong chemicals to achieve a black finish, a fibre laser can produce the same result without chemicals and even create a small range of colours in addition to black.

Customer Benefits

For customers, the most significant advantage is speed and consistency. Plaques can now be produced and shipped within 24 hours. The process requires no drying time for inks or sprays and eliminates the risk of uneven coverage, which can occur with older CO₂ laser engraving methods.

Broader Applications

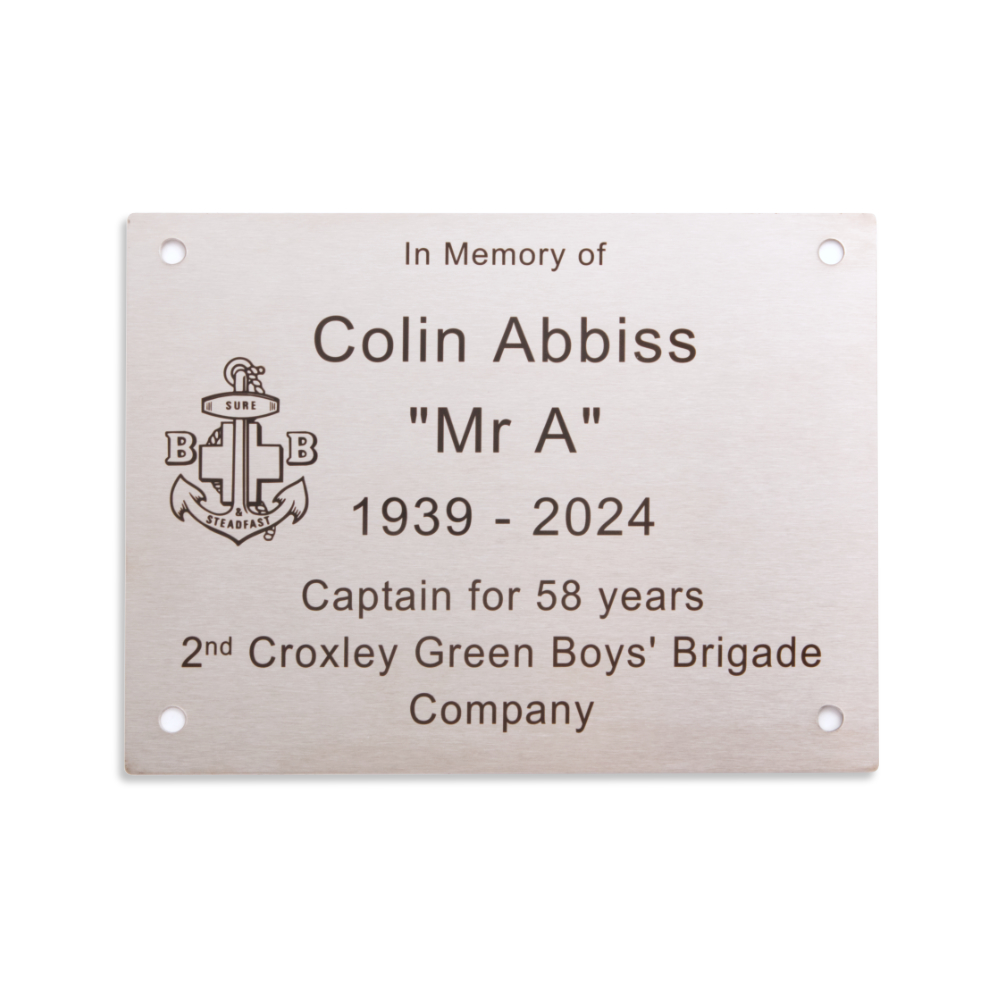

Since introducing the fibre laser engraver, Earth Anchors has produced a range of plaques on both brass and stainless-steel plates. The technology has also enabled the creation of QR-coded stainless plaques, which can be used in a variety of settings. Applications include ordering systems for restaurants and pubs, links to online memorial pages, and information points for public spaces and heritage sites.

Customers interested in more traditional options can also view examples of stainless steel memorial plaques and memorial wall plaques, which demonstrate the different finishes now achievable with the new technology.

Quick Contact

Newsletter Sign Up

Keep up to date by subscribing to our newsletter and see what we could do for you.

Unsubscribe at any time.